Challenge

In 2011, Associated Grocers wanted to strengthen compliance with the recently signed Food Safety Modernization Act.

Solution

C.H. Robinson brought together Associated Grocers, FoodLogiQ, and LoBue Citrus to develop traceability capabilities for inbound, slotted, and outbound product to increase efficiencies into Associated Grocers’ operation.

Results

Associated Grocers used technology improvements and software solutions from FoodLogiQ to achieve their compliance goals. They also added unexpected new efficiencies that could have a bottom-line impact of .1 to .3 basis points.

“We can now trace product from the field to specific slots inside the warehouse, and all the way forward to the stores in minutes.”

- MIKE BOVE

VICE PRESIDENT OF PERIISHABLE PROCUREMENT

“Scanning GTIN label barcodes makes our information 100% accurate. It eliminates rework and frustration at the store level.”

- MIKE BOVE

VICE PRESIDENT OF PERISHABLE PROCUREMENT

Associated Grocers, Inc., of Baton Rouge is a forward-thinking retail operation support center that aims to keep its 200 plus member-owners competitive in the market and at the forefront of technological developments.

The Pilot: Moving traceability from concept to reality

Associated Grocers and C.H. Robinson have collaborated for more than a decade to create supply chain efficiencies. Recently, they worked together to streamline Associated Grocers’ buying process. C.H. Robinson facilitates grower bids, negotiations, logistics, and provides a single invoice that breaks down product and transportation costs. C.H. Robinson’s capabilities allow Associated Grocers’ category specialists more time for face to face interactions with their member-owners so they can build relationships that enhance business.

When Mike Bove, Associated Grocers’ vice president of perishable procurement, decided it was time to implement new Produce Traceability Initiative (PTI) capabilities, he contacted C.H. Robinson. Working together, the companies selected the right technology and capable grower. They created the produce industry’s first end-to-end, multi-party traceability route through independent operational environments from a grower all the way to a retailer.

Tracing product back to the field requires more detailed data than a standard UPC code can provide. To provide such data, growers must label each produce case with a Global Trade Identification Number (GTIN) and each pallet with a Serial Shipping Container Code (SSCC) expanded barcode. By scanning such labels and storing key data about the case of produce—including the item, the varietal of the item, and which lot the case is connected to from last packing activity—Associated Grocers would attain traceability for inbound product, reduce errors, and increase efficiencies.

Associated Grocers relied on C.H. Robinson’s extensive research of PTI solutions and selected the best software—FoodLogiQ—to help both retailers and growers with traceability. FoodLogiQ’s easy-to-use case and pallet labeling software works with smart printers for increased operational effectiveness with lower costs in both field and packing shed environments. If FoodLogiQ’s solution worked between one grower and the Associated Grocers operation, expansion to multiple retailer operations and shippers looked promising.

On the supplier side, C.H. Robinson selected LoBue Citrus to participate in the pilot program. LoBue Citrus packs citrus (oranges, lemons, and other specialty fruit) for C.H. Robinson under the Tropicana® label. For the pilot, LoBue Citrus would pack, label, and ship Tropicana® fresh oranges to Associated Grocers’ warehouse using FoodLogiQ, which was already in service in their operation.

To prepare for the pilot, Associated Grocers updated its Warehouse Management System (WMS) so that scanned label information would populate the right fields within that system. They incorporated finger and wrist scanning hardware into their voice system, and tested to ensure that their WMS would recognize both voice and scanned information.

Creating faster tracebacks

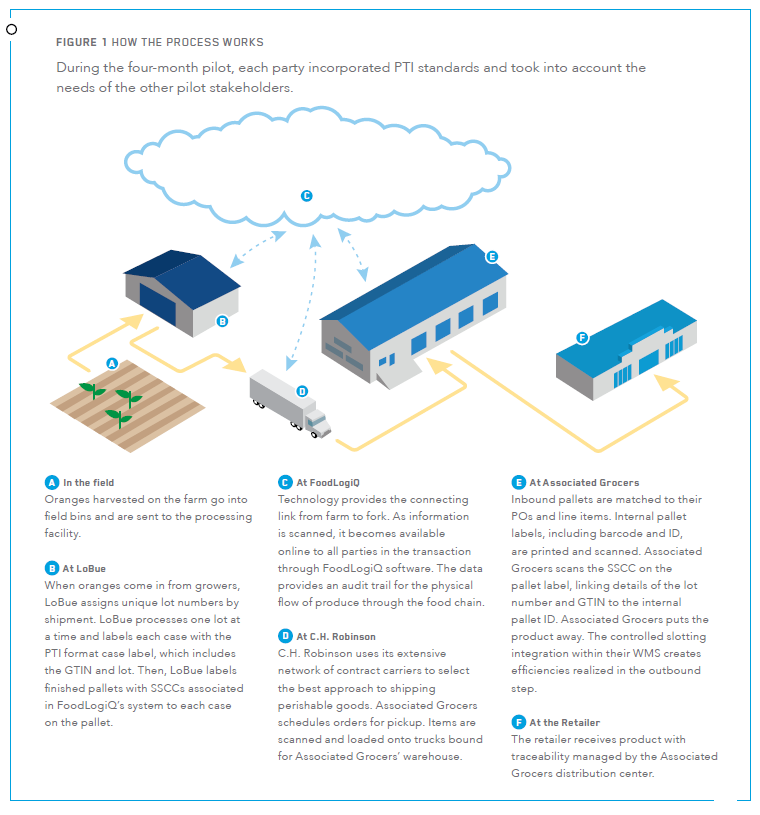

The implementation proceeded smoothly for the four months of the pilot, with excellent communication between all parties, according to Bove (see Figure 1). Although scanning every inbound case added steps to the receiving process, Bove began to see efficiencies on outbound shipments as the pilot moved into the next phase. “Once we could scan both inbound and outbound, we knew exactly what was loaded on the truck, and had proof of where every item that was shipped to us had gone. We could trace items at the grower, warehouse, and store levels. That enabled faster tracebacks. Having the ability to do this with C.H. Robinson and FoodLogiQ was the right direction to go, and this was the right time to test it,” said Bove.

Efficiency beyond expectations

Bove says it’s too soon to fully understand the long term ROI for traceability. “Proof of that will come during the first recall,” he comments. But, he already knows there will be efficiencies in other areas besides produce.

Bove says, “Scanning GTIN label barcodes makes our information 100% accurate. It eliminates rework and frustration at the store level. We have proof that the product was on the truck, so there won’t be short order reports, and we won’t have to rework invoices because the system is more accurate. Additionally, we discovered these efficiencies work in fresh meats and other categories. That was a huge side benefit we weren’t expecting.” Bove expects to see an increase in gross profit and labor savings both at the wholesale and retail level with these improved efficiencies.

Although Bove concedes there are costs involved in implementing this type of technology, he thinks it’s important for the industry to do everything it can to address food safety. He’s not too concerned that regulations will change traceability requirements down the road. “I think companies need to move forward. We’ve proven that it can be done with the right tools. I’m willing to make that investment. Stores will want to buy from us when we can assure them that if there is a recall, we can identify the source within hours so they can get it off the shelf. It’s an advantage for our members and their customers.”

Associated Grocers and C.H. Robinson are now working on the next building block to food safety—data synchronization so everyone in the supply chain has the same information about a product, the pallet ties, pictures of the product, and the right attributes of the product. C.H. Robinson is preparing to roll out FoodLogiQ software with other retailers and growers. As a company that sources as well as ships produce, C.H. Robinson will make the same investments in traceability technology as their trade partners. Jim Lemke, C.H. Robinson’s senior vice president of sourcing, believes that using FoodLogiQ at a few cents a case is worth it to provide better traceability and a safer food supply.

To learn more about C.H. Robinson’s programs, connect with an expert today.