Top Way to Make Freight Attractive: Reduce Detention

Transportation prices fluctuate with supply and demand. When equipment is scarce, increase load acceptance by fixing carriers’ most-hated issue: detention.

In the “perfect market” of transportation, no single carrier and no single shipper control enough of the market to influence pricing. That makes things challenging as the market gets busier and there is more freight than there is equipment. Many shippers would say we are currently in a market such as this, where carriers can be choosier about who they will work with and what freight they will haul. They may compare customers at such times, rejecting loads from shippers who make it hard to do business in favor of those who make it easier and more efficient.

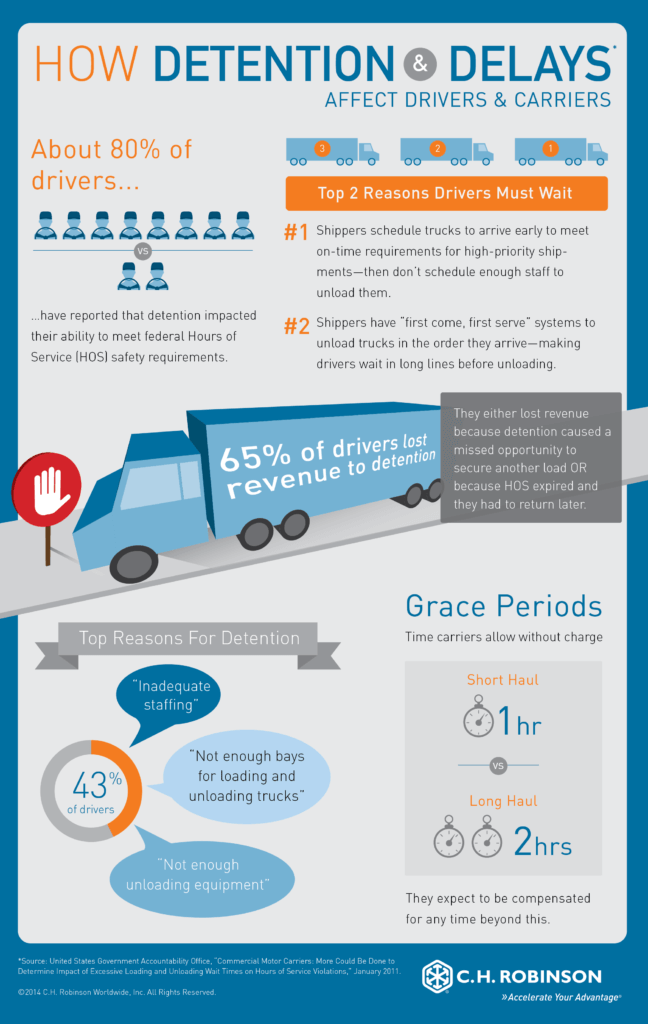

So how can you appeal your freight to carriers? There are plenty of things you can do to improve compliance to routing guides and increase load acceptance. One of those things is focusing on factor that is particularly annoying to carriers: detention and delays.

How Truckload Detention and Delays Affect Carriers

In February 2014, an advisory committee prioritized detention as one of 38 items for the Federal Motor Carrier Safety Administration (FMCSA) to consider pitching to Congress to include in the next highway reauthorization bill. The committee agreed that excessive detention time forces drivers to operate unsafely, a form of driver coercion.

The Commercial Carriers Journal (CCJ) reported one committee member saying that, “Shippers should: be held responsible for holding the truck up. FMCSA needs to pursue what they can do to ensure that when a truck is held up, the company and/or the driver are paid.” The committee chairman, Stephen Owings, concurred. He said, “That whole concept should be expanded to require that the whole ‘chain of responsibility’ is on the hook financially and every other way for doing anything to encourage dangerous behavior by the truck drivers.”

How to Reduce Truckload Detention & Delays

These are common ways shippers can reduce detention and delays:

- Limit Backlogs: Facility limitations can create backlogs of vehicles needing to be loaded or unloaded. Shippers can establish processes so their facilities do not overschedule appointments and maintain adequate staff and equipment to handle the number of trucks scheduled.

- Preset Delivery Appointments: Shippers can use a transportation management system (TMS) to preset delivery appointments, with standardized guidelines and operating procedures for all carriers to follow.

- Avoid Missing Appointments: Shippers can schedule carriers to arrive every 30 minutes, with a goal of having the carrier either loaded or unloaded within 90 minutes. Carriers who miss appointments must wait to be unloaded after carriers that make their scheduled appointment times.

- Gain Visibility with a TMS: A TMS can measure and analyze detention issues to find out where they occur and help implement procedures to reduce them. In addition, reporting from the TMS can pinpoint schedules that fill up in advance and lead to service failures at the receiver’s location.

Final Thoughts

No matter what the market conditions are, it’s always a good idea to make sure you’re the kind of shipper who’s easy to work with—something that will get carriers’ attention when the market swings in their favor.

Carriers have preferences for the shippers they choose to work with frequently. Gain more ideas on how to become a preferred shipper.