Understand landed costs—from upstream to downstream

Combat challenges. Manage network complexity. Gain enhanced visibility. Do it all and more with Item-level Solutions from C.H. Robinson. When you own every detail, you can make smarter, faster decisions that enhance operations, improve efficiency, and drive cost savings.

Configurable building blocks that meet you where you are

See everything in real-time

Improve inbound and outbound visibility through custom, SKU-based alerts. Build detailed cost breakdowns by product, freight, and component for better oversight and control over total landed costs.

Execution control

Turn purchase order demand into a full transportation plan executed by C.H. Robinson. Boost data accuracy while monitoring performance and costs in real time with configurable vendor scorecarding.

System-wide efficiency

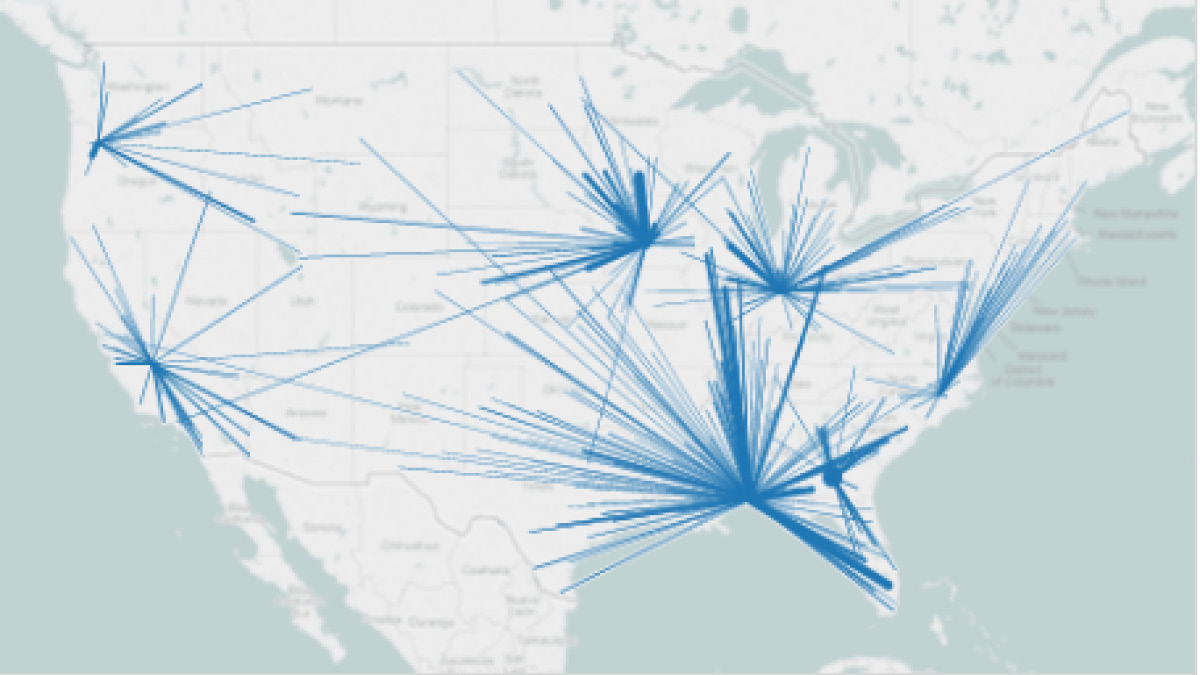

Collaborate with supply chain engineering experts to optimize distribution networks, warehouse locations, transportation routing, and modal selection. On average, customers save 10–30% on logistics costs.

SKU-level precision

Align your inventory strategy with service and cost goals. Achieve SKU-level precision through inventory optimization. Then take it a step further with additional services like automated replenishment, redistribution, and omnichannel fulfillment.

See how Item-level Solutions can benefit your business

Real-world example

Removing the complexity from an automotive supply chain

PO created

Automaker places an order for 500 steering wheels to deliver on Thursday.

Confirmation received

The supplier confirms shipment—but only 480 are available and it will deliver Saturday (two days late).

Items shipped

Track each steering wheel in real time—know what’s on the move.

Items arrived with discrepancy

Only 475 steering wheels arrive. Where are the missing five?

Root cause analysis conducted

Item-level visibility helps trace the issue—five steering wheels were damaged in transit. Remaining items on the PO will be fulfilled later.

Process optimized

Use insights to improve supplier performance and reduce waste. Govern against quantity and timing discrepancies.

What sets C.H. Robinson Item-level Solutions apart

Auto supplier reduces overspending and increases visibility

Challenge

Top 5 global auto supplier struggled with visibility to goods in transit, causing late reactions to issues and inbound supply chain problems.

Solution

Using a 52-week rolling forecast and supply chain details from the shipper, C.H. Robinson created a weekly dynamic route and optimized inbound load plan.

Result

In addition to $4–5 million annual cost savings and 40% reduction in supply chain emissions, the supplier’s routes are optimized for actual demand.

Qdoba sees the full picture and saves millions

See how a leading quick-serve restaurant gained visibility to their nationwide network and improved service.

Testimonios

Only C.H. Robinson can provide both technology and execution at the item level

C.H. Robinson C.H. Robinson |

Software Providers | Execution Providers | Other Providers | |

|---|---|---|---|---|

| Visibility at the item level | ||||

| PO management | ||||

| Supply chain engineering | ||||

| Inventory optimization | ||||

| Data & insights | ||||

| Execution | ||||

| Global scale |

= Specific, disparate providers