Challenge

CSA required technicians to install specialized kiosks at retailers across the country. Because their supply chain heavily relied on both logistics providers and technicians, CSA experienced excessive logistics and installation costs.

Solution

The company outsourced to C.H. Robinson. In addition to a new forecasting process, C.H. Robinson helped CSA change the configuration process prior to delivery, eliminating the need for trained technicians to install.

Result

Drivers delivering the kiosks can now set up and install the preconfigured kiosks. This reduced the need for onsite technicians by 70% and means kiosks are running within 30 minutes of delivery rather than 48 hours—all at a fraction of the cost.

“Before outsourcing our entire supply chain to C.H. Robinson, there were so many moving parts that it really hindered our growth. C.H. Robinson carved out a new solution that hadn’t existed before. ”

- LUC VALLIERES

GENERAL MANAGER AND VICE PRESIDENT

“When my customers ask where their shipments are, I use Navisphere® to track the machine, no matter where it is. With C.H. Robinson, I can provide them with an accurate answer, every time. ”

- LUC VALLIERES

GENERAL MANAGER AND VICE PRESIDENT

As a nationwide company, CSA provides service solutions to businesses across many industries. One division is CSA Kiosk Solutions (CSA). From design and manufacturing to installation and post-deployment, CSA offers complete services for all aspects of a kiosk’s life cycle.

Inefficient supply chain limits growth

CSA works across industry lines—from blood pressure machines and overall wellness kiosks in the medical industry to Automated Teller Machines (ATM) in the financial industry.

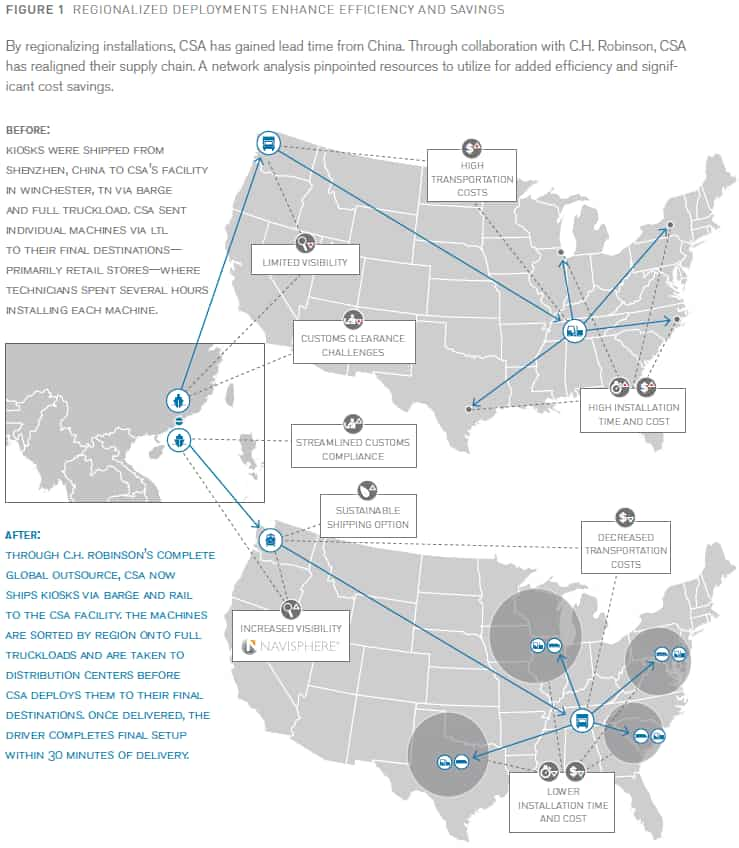

The majority of each kiosk is manufactured in the port city of Shenzhen, China, and final assembly is completed at a CSA facility in the U.S. CSA typically transported the constructed machines by ship and full truckload to their facility in Winchester, TN. The process was scattered across several companies, which meant limited visibility and few tracking capabilities—especially with customs compliance and regulations. This often led to additional complications, primarily with on time deliveries.

Once CSA installed the final components at their facility, they paid one of several transportation providers to deliver the specialized kiosks to their final destinations by less than truckload (LTL). CSA dispatched technicians to each retail location to uncrate, install, configure, and test the specialized machines—a process that could take several hours. And because store delivery could occur as early as 48 hours before the scheduled installation, technicians were not always available. These details made CSA’s supply chain heavily reliant on both logistics providers and technicians, which resulted in excessive logistics and installation costs.

Superior solutions through Collaborative Outsourcing®

CSA wanted a streamlined, efficient supply chain to boost growth potential. The company chose C.H. Robinson as a complete outsource solution because of their:

- People. CSA would receive a personal approach from empowered people with innovative strategies and problem solving abilities.

- Network. C.H. Robinson’s global network would provide local knowledge, regional expertise, and global capabilities to move CSA’s kiosks from one side of the world to the other.

- Portfolio of Services . The variety of services offered by C.H. Robinson would include consistent capacity and service levels, consulting expertise, and collaborative, innovative solutions.

- Scale. CSA could leverage C.H. Robinson’s industry-leading capacity and large shipment volumes to improve efficiency and create marketplace advantages.

Luc Vallieres, general manager and vice president, CSA Kiosk Solutions Division, stated, “C.H. Robinson’s personal approach and unique solutions will help quickly reach our business goals.”

After a network analysis, C.H. Robinson and CSA developed a proactive, collaborative approach to reduce spend and improve efficiency throughout the supply chain. First, they mapped and pooled upcoming installations by region, which helped determine manufacturing needs months in advance.

Better planning meant other areas of the supply chain fell right into place. With additional lead time, the company now uses rail services from the port city to Winchester, TN for a sustainable, cost effective option. After assembly, production, and testing is complete, the machines are loaded onto full truckloads bound for distribution centers, and then are delivered by “milk runs” to each store.

Better planning meant other areas of the supply chain fell right into place. With additional lead time, the company now uses rail services from the port city to Winchester, TN for a sustainable, cost effective option. After assembly, production, and testing is complete, the machines are loaded onto full truckloads bound for distribution centers, and then are delivered by “milk runs” to each store.

C.H. Robinson’s global experts helped CSA simplify the regulations process, obtain better visibility using Navisphere®, C.H. Robinson’s single, global technology platform, and re-engineer the container packaging strategy to reduce international shipping costs by 50 percent.

C.H. Robinson also facilitated a new in-store installation process. CSA now configures the networking, application, and specific store settings at their facility so each is machine functional before delivery. Since the implementation process is nearly complete before the kiosk even leaves the facility, technicians are no longer required for every installation. The reduced number of hours CSA technicians are deployed in the field has significantly reduced personnel costs.

The same drivers who deliver to the stores now follow a checklist to set up and install the preconfigured kiosks. This change not only reduces the need for onsite technicians by 70 percent, it also improves customer service and reduces potential damages caused by overeager customers. Health and wellness kiosks that test blood pressure are a critical piece of equipment for pharmacies. The faster they are functional, the more value the end user receives. On average, machines are now installed and running within 30 minutes of delivery rather than 48 hours—and at a fraction of the cost.

Once a kiosk is installed, C.H. Robinson also handles post-installation customer service calls. As part of the new process, every store receives a phone call asking how their installation experience was. This additional step not only ensures happier customers, but also helps CSA and C.H. Robinson continually evaluate and improve the process for the best possible service.

Always improving for lasting results

“When my customers ask where their shipments are, I use Navisphere to track the machine, no matter where it is. With C.H. Robinson, I can provide them with an accurate answer, every time,” Vallieres says. In addition, C.H. Robinson has helped CSA smooth day to day supply chain complexities, realize fast growth, develop impeccable efficiency, and find maximum cost savings.

CSA can now handle growing demands. They have tripled their weekly capacity for kiosk installations without increasing the number of technicians. The more efficient supply chain has saved the company 25 percent in overall supply chain costs.

CSA is now collaborating with C.H. Robinson on new projects, including the possibility of replicating this model across more industries, incorporating a managed parts warehouse process, and conducting further analysis for greater supply chain efficiencies from inception to installation.

When asked about future projects, Vallieres explains, “I look forward to more growth with C.H. Robinson. I can’t wait to achieve even better results so we can always offer the most to our customers. C.H. Robinson’s personal approach and unique solutions will help us quickly reach our business goals.”

To learn more about C.H. Robinson’s programs, connect with an expert today.