Challenge

Steel kegs are the traditional choice for transporting many popular beverages; but they’re heavy, costly, and require cleaning.

Solution

C.H. Robinson partnered with Lightweight Containers to provide a full service supply chain solution to help with order tracking and global visibility.

Results

- Lighweight Container's growing customer base

- Lightweight Container's confidence, and clear view of the North America supply chain

“Our shipping needs will continue to grow as our customer base expands. Thanks to C.H. Robinson, our supply chain will be able to keep up. ”

- ANITA VEENENDAAL

CEO LIGHTWEIGHT CONTAINERS

“Because orders don’t have to travel as far from the warehouse to reach customers, we can be proud of fast turnaround times reduced impact on the environment. It’s something our customers really appreciate. ”

- ANITA VEENENDAAL

CEO LIGHTWEIGHT CONTAINERS

When an order comes in at the end of the day, the logistics team at Lightweight Containers, Inc. doesn't worry that it won't process in time. They just have to get the basic order information added into Navisphere® and they know that Mindy, their C.H. Robinson account representative, will take care of the rest.

And it’s not because they expect Mindy to work overtime. It’s because she’s in the United States, while the order process team of Lightweight Containers, Inc. is based in the Netherlands. So her day is just beginning when the Lightweight Containers, Inc. order process team is heading home. “The time difference between us and our United States customers is not a problem because C.H. Robinson shares our drive for perfect service,” explained Anita Veenendaal, CEO of Lightweight Containers Inc.

Unique alignment: A promise to quality service

Using the time difference as a benefit is just one example of the service Lightweight Containers, Inc. has come to expect from C.H. Robinson over the past several years. Peter van Strijen, who is responsible for logistics, and his team also recognize that Mindy will go above and beyond to make sure Lightweight Containers, Inc. receives the best possible price through mode optimization—without sacrificing delivery times or product safety.

“We like that our account manager thinks with us rather than just what’s best for C.H. Robinson,” shared van Strijen, “C.H. Robinson’s commitment to quality closely aligns with the promises we make to our own customers.”

Lightweight Containers previously worked with several logistics providers throughout North America—of which C.H. Robinson was one. But that only gained them a fractured view of what was happening to their supply chain in the United States and Canada. It required added work for Peter’s team in the Netherlands too—they were always checking and rechecking that orders were processed and inventory levels were satisfactory.

“With C.H. Robinson, we could stop double checking every order. Navisphere means everything is organized and in one place from the start,” stated van Strijen, “The clear view we now have of our North America supply chain wouldn’t be possible if we were still juggling multiple providers.”

Focused warehouse strategy better serves customers and timelines

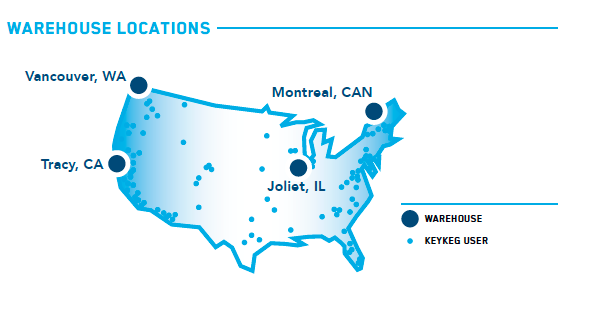

Sometimes thinking differently about a situation requires fresh eyes. Rather than limiting inventory to a central warehouse location, C.H. Robinson’s team ran models to find the ideal warehouse locations close to customers. Based on these scenarios, Lightweight Containers adjusted their warehouse locations.

"Because orders don’t have to travel as far from the warehouse to reach customers, we can be proud of fast turnaround times reduced impact on the environment. It’s something our customers really appreciate,” shared Anita Veenendaal.

Facing stiff competition with a strong competitive advantage

While the average beer, wine, or coffee drinker doesn’t pay much attention to what kind of container their drink is transported in, for those in the beverage industry, it is a big decision.

Steel kegs are the traditional choice for transporting many popular beverages; but they’re heavy, costly, and require cleaning. Not to mention they’re often stolen and must be shipped back to the owner—sometimes traveling thousands of miles to do so. More recently, industry-leading companies, like Lightweight Containers, are offering one-way, recyclable kegs as a cost-effective and sustainable alternative. Recyclable kegs can save companies more than 60% on transportation costs thanks to their low weight and only one way shipping requirements.

Their two product families, KeyKeg® and UniKeg®, give large and small breweries, family-owned wineries, and other beverage distributors (including coffee and cider) the chance to safely and sustainably ship products farther distances without the heavy investment steel kegs require, or penalty payments in case of loss or late return.

In a growing industry, Lightweight Containers faces fierce competition, but their robust warehousing processes and supply chain visibility help set them apart. “Providing good information about deliveries is part of our commitment to service,” stated van Strijen, “That’s why we appreciate the external tracking tool from C.H. Robinson. It allows us to share a customized link with customers so they can always see where an order is in the process—without needing to log into Navisphere.”

A scalable supply chain for a growing business

With customers coast to coast, it’s clear to see that companies across North America like Lightweight Container products—and the service they receive. With the launch of their latest product, UniKeg, which is made especially in the United States for North America customers, Lightweight Containers expects even more growth.

“When we started working solely with C.H. Robinson in North America, we knew that a full service supply chain solution was the right choice,” explained Veenendaal. “Our shipping needs will continue to grow as our customer base expands. Thanks to C.H. Robinson, our supply chain will be able to keep up.”

To learn more about C.H. Robinson’s programs, connect with an expert.

To learn more about KeyKeg and UniKeg visit www.keykeg.com, and www.unikeg.com

KeyKeg® and UniKeg® are registered trademarks of Lightweight Containers. Used with permission.